Laser cutting a fr4 pcb with a co2 fiber break board atmega 2560 duration.

Laser cut fr4 pcb.

High power co 2 laser 10µm wavelength the co 2 laser can thermally cut through fr4 glass fibers and other rigid and flex circuit substrates at comparatively high speed but with noticeable heat effect on the edge of the cut for most substrates.

The fiber laser enables us to engrave the copper layer of the fr1 and.

Back to tutorial index.

For the fab academy 2015 at opendot in milan we have a new laser cutting machine a trotec speedy 100 flexx the flexx line of laser cutters has both co 2 and fiber laser technologies.

Pierluigi de palo 8 763 views.

Laser routing can be performed using either.

Laser marking is also possible if there is a solder mask on the surface of the.

Custom pcb prototyping using a laser cutter.

This is a process i have perfected after several prototypes i created as part of my t.

Other types of common lasers due to the cold ablation attributes of the uv wavelength it is ideal for pcb depaneling as it greatly reduces the heat affect zone haz allowing the beam to cut right up to the edge of your board s.

60 watt co 2 laser 30 watt fiber laser.

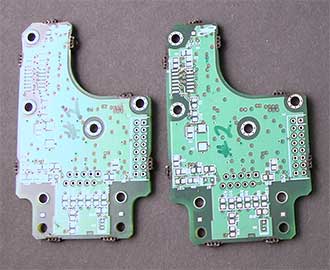

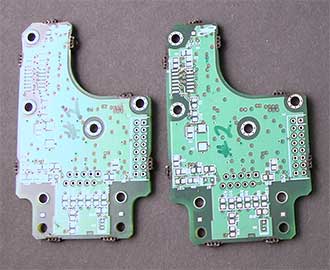

2 layer circuit boards using laser cutter chemical etching.

Laser marking of fr 4 g10 with a co 2 laser carbonizes the surface of the epoxy creating a dark visible mark on a lighter surrounding substrate.

I am going to walk you through the process of prototyping a printed circuit board using a laser cutter and supplies from your local radioshack and hardware store.

Laser cutting of fr 4 g10 with a co 2 laser produces a blackened carbonized edge that can be cleaned with a solvent.